Registered to UNIDO ITPO Tokyo’s STePP

InviroshieldM5 is registered to Sustainable Technology Promotion Platform (STePP) of United Nations Industrial Development Organization (UNIDO) Investment and Technology Promotion Office, Tokyo (ITPO Tokyo)

(URL: http://www.unido.or.jp/en/activities/technology_transfer/technology_db/)

URL: http://www.unido.or.jp/en/technology_db/6450/

'Inviroshield M5' eliminates pathogenic microorganisms and helps to reduce infections in the hospitals. This facilitates decrease in ALOS (average length of stay), which will not only reduce medical expenditure but also increase the treatment availability to deprived patients in developing countries, ensure healthy lives and promote wellness for all. Saved funds can also be utilized for nutritional supplements for malnourished children.

In India, central government hospitals and municipality hospitals adopted this bio-decontamination program since last 5 years. The results of this technology are significant in the process of reduction of Infant Mortality rate in the Safdarjung hospital (Central Government Hospital). Currently this technology is also being adopted in AIIMS (All India Institute of Medical Sciences).

We have been serving Indian Market since 2008. Till date, total 800,000 sq. ft. has been treated by using 'Inviroshield M5' in Indian healthcare Institutes alone.

Major Features and Advantages

・'Inviroshield M5' is by coating for indoors, the risk of nosocomial infections can be reduced over the long term.

・When the coated surface is irradiated with light, the anti-bacterial effect appears due to the photocatalytic oxidation reaction, which reduces the labor and cost of disinfection work for a long time.

・Using 'Inviroshield M5' reduces the usage of chemical disinfectants which pose threat to human and the environment.

・The improper use of chemical disinfectants adds to the global concern of antimicrobial resistance, which can be reduced using self-generative 'Inviroshield M5'.

・It also helps in reducing secondary infections by microbial elimination and thereby contributes in additional cost reduction that occurs due to hospital acquired infection.

・Saved funds can be used for extending medical facilities to the needy and deprived population and can also be utilized for betterment of healthcare infrastructure.

・Our motto is to maintain less of microbes, hence less of Infection and thereby less of deaths. Because, every life matters.

Possible applications

・The visible light responsive photocatalyst ‘Inviroshield M5’ is coated with an air-drive type spray gun on the walls, ceilings, furniture, etc. of hospital operating rooms and hospital wards. The coated surface exhibits an antibacterial effect for a longer period of time than the quaternary ammonium salt used for disinfection due to the photocatalytic oxidation reaction caused by light such as indoor fluorescent lamps, LED lamps and sunlight.

Fig. 1 Tools for coating (Inviroshield, spray gun, air compressor, etc.)

Fig. 2 Inviroshield coating in the hospital

・Once treated, the place can maintain a long-term antibacterial effect, so a hygienic environment can be maintained even in places where the frequency of cleaning is low. It is possible to prevent nosocomial infections caused by pathogens entering from outside. In particular, the medics, paramedics and patients can reduce the risk of getting sick and germs in the operating room, enabling safe medical work in the hospital.

・These not only reduce health care costs, but also increase the availability of treatments for patients in developing countries to ensure healthy lives and promote the well-being of all.

・Inviroshield M5 can be used in all applications and all areas where there is a threat of biological (microbial) contamination/spread through surface media. Inviroshield M5 can be applied in indoor as well as outdoor surface where protection from microbes- microbial colony, mold, biofilm is required.

Competitive advantage

・Based on the reports obtained after ‘Inviroshield M5’ application in the healthcare settings we ensure the reliability of our innovative solution with frequent checkups. This solution is confirming durable for at over one year after application. (See Appendix 1)

・’Inviroshield M5′ coating worker can do this by learning how to handle some equipment and testing machines and how to coat for several hours. Advanced skills or long-term training are not required.

Cost performance

・Disinfection worker has to disinfect all surface for the time and again as per schedule at least once a day, or whenever the surface gets contaminated.

・In addition, all areas must be disinfected because the difference between contaminated and uncontaminated areas is not known.

・In order to achieve the same disinfecting effect as Inviroshield M5 with conventional chemical disinfectants, it is necessary to disinfect the chemical disinfectant dozens of times a day.

・This is because the treated surface of Inviroshield M5 is always anti-bacterial condition.

・Therefore Inviroshield M5 can reduce costs by replacing liquid chemical disinfectants (e.g. quaternary ammonium cations, H2O2, phenolic compounds, etc.).

・In many countries, drug-resistant bacteria appear due to inappropriate use of chemical disinfectants, causing problems such as secondary damage to patients.

・In the United States, violations that do not comply with the disinfectant manufacturer’s procedures are subject to prosecution under the FIFRA Act.

・Compared to this, Inviroshield M5 is a one-time application that is always active for anti-bacterial effect and does not require repeated applications nor adherence to any specified conditions.

・Also, anti-bacterial effect of Inviroshield M5 is by photocatalysis decomposed effect, unlike chemical disinfectants, so no drug-resistant bacteria are produced.

・The contaminated area becomes a non-contaminated area over time due to the photocatalysis effect of InviroshieldM5.

・Furthermore, Inviroshield M5 treatment also be able to take the self-cleaning effect and smelling gas decomposed effect.

・Inviroshield M5 is a very cost effective and convenient solution for healthcare establishments.

・As a result, when Inviroshield M5 was treated, the antibacterial state can be maintained for one year at a cost of about 80% of the daily chemical disinfectant work.

・The reduced cost of approximately 20% can be returned to use for the hospital equipment, medical staff, patients, etc.

![[PDF]](http://www.unido.or.jp/common/img/icon_pdf.png)

・Application process

See attached file: INVIROSHIELD OPERATION STEPS

Performance

・Our original photocatalytic coating agent uses a visible light responsive photocatalytic material that combines copper, iron and titanium oxide.

・The visible light responsive photocatalyst used is effective not only for sunlight entering through windows, but also for indoor fluorescent lights and LED lights.

Technical maturity / Past record of introduction

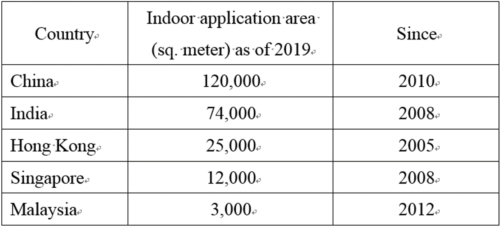

・Our photocatalyst coating agent is used in the city hall buildings of Taiwan and Hong Kong and in ambulances in order to prevent the spread of “severe acute respiratory syndrome” (abbreviation: SARS), which prevailed in 2003.

・After that, ‘Inviroshield M5’ was developed in 2005 as a coating agent that can effectively show the photocatalytic effect for the indoor space.

・We have been supplying Inviroshield M5 in Hong Kong, India, Singapore, China and Malaysia until now.

・We are serving Indian Market since 2008. Till date, total 74,000 sq. meter. have been treated using only ‘Inviroshield M5’, in Indian healthcare Institutes alone.

・We are financially stable and has sufficient experience, expertise, resources, and manpower to take the technology around the world.

・In India, central government hospitals and municipality hospitals adopted this bio-decontamination programme since last 5 years. The results of this technology are significant in the process of reduction of Infant Mortality rate in the Safdarjung hospital (Central Government Hospital). Currently this technology is also being adopted in AIIMS (All India Institute of Medical Sciences).